STATCYL PRODUCTS

Conductive Plate Sleeve – STATCYL

Conductive Bridge Sleeve – STATCYL

Conductive Plate Sleeve – STATCYL

Plate sleeve made of epoxy-based composite material with carbon for static current conduction.

Resistant to aggressive solvents and high dimensional stability.

Total Resistance

Resistance to aggressive solvents, total encapsulation, prevents solvent and moisture absorption.

Honeycomb Structure

The exclusive honeycomb structure provides an optimal balance between robustness, stability, and low weight.

Protection

Side faces protected with impact-resistant material.

Speed

Suitable for high-speed printing.

Adhesion

Surface allowing optimal tape adhesion and easy removal after printing.

Metal Notch

Available from 6mm thickness onwards.

Optional Internal Protection

Metal protective ring on the notch side to prevent interior damage (Thickness > 12mm).

Static Current Drainage

Coated with carbon-based material for proper drainage of static current generated during the printing process.

Warranty

One year for manufacturing defects.

TECHNICAL SPECIFICATIONS

Tolerances: TIR ≤ 0.020mm (mounted on a mandrel with TIR ≤ 0.005mm) – Outer diameter +/- 0.02mm

Hardness: 75 – 80 shore D

Working temperature: 16ºC – 40ºC

Working pressure and flow rate: 6 – 8 bar and 12 liters/second

Available in wall thicknesses from 1.5mm to 150mm.

Electrical resistance: < 1 MOhm

For larger sizes, please inquire.

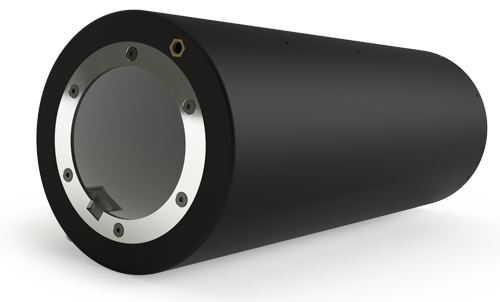

Conductive Bridge Sleeve – STATCYL

Bridge sleeve made of epoxy-based composite material with carbon for static current conduction.

Excellent dimensional stability and very low weight thanks to the honeycomb design developed for large thicknesses.

Static Current Drainage

Used in conjunction with sleeves from the Statcyl line to allow proper drainage of static current generated during the printing process.

Electrostatic Discharge

Conductive coating made of carbon-based epoxy to allow electrostatic discharge.

Total Resistance

Resistance to aggressive solvents, total encapsulation, prevents solvent and moisture absorption.

Honeycomb Structure

The exclusive honeycomb structure provides an optimal balance between robustness, stability, and low weight.

Protection

Side faces protected with impact-resistant material.

Speed

Suitable for high-speed printing.

Easy Assembly and Disassembly

Optimal distribution of surface air allowing easy sleeve assembly/disassembly.

Smooth Assembly

And good fixation to the mandrel.

Internal Protection

Metal protective ring on the notch side to prevent interior damage.

Warranty

One year for manufacturing defects.

TECHNICAL SPECIFICATIONS

Tolerances: TIR ≤ 0.015mm (mounted on a mandrel with TIR ≤ 0.005mm) – Outer diameter +/- 0.015mm

Hardness: 75 – 80 shore D

Working temperature: 16ºC – 40ºC

Working pressure and flow rate: 6 – 8 bar and 12 liters/second

Electrical resistance: < 1 MOhm

Available in wall thicknesses from 12mm to 150mm and in pneumatic or through-flow versions.

For larger sizes, please inquire.

Contact us

Please fill out the form below and we will contact you shortly.

Valentín Gomez 553, Villa Lynch, Buenos Aires, Argentina

+54 011 5217 2723

+54 9 11 5099 5259

ventas@kypsrl.com.ar